Tips for Choosing 3D Modeling and Slicing Software

Designing with Modeling software is the foundation part for productions in most areas, such as Games, Movies, Photography, and so on. When we are doing 3D printing for industrial usage or personal designs, we also need some professional modeling software for this purpose. This article will give you some advice on how to choose modeling and slicing software for 3D printing. From two aspects of analysis, one is the user group, respectively are beginners, amateurs, advanced users, and professionals. Another aspect is the expense, from free to charge, which is satisfying your every need. What's more, there are some kind tips for your work.

1. Modeling Software

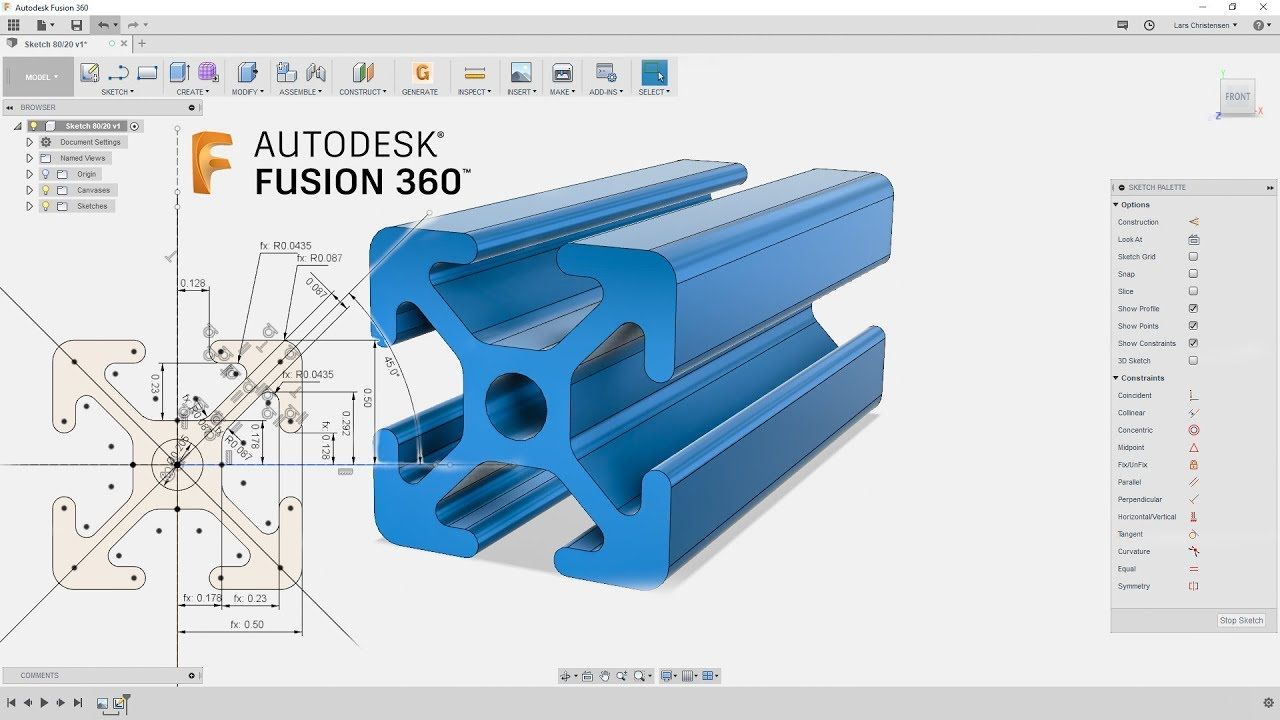

a) Fusion 360 Personal License: It is currently one of the well-known CAD systems, professional software for creating complicated model designs, and is popular with amateurs and professionals. Fusion 360 is a cloud-based program which means design teams could collaborate together on the same project. Another reason to choose it is that Fusion stores a number of design models which you could choose, including solid, mesh, and free shape. Fusion 360 adopts a monthly payment subscription and is free for three years for new customers, and $595 per year for commercial users.

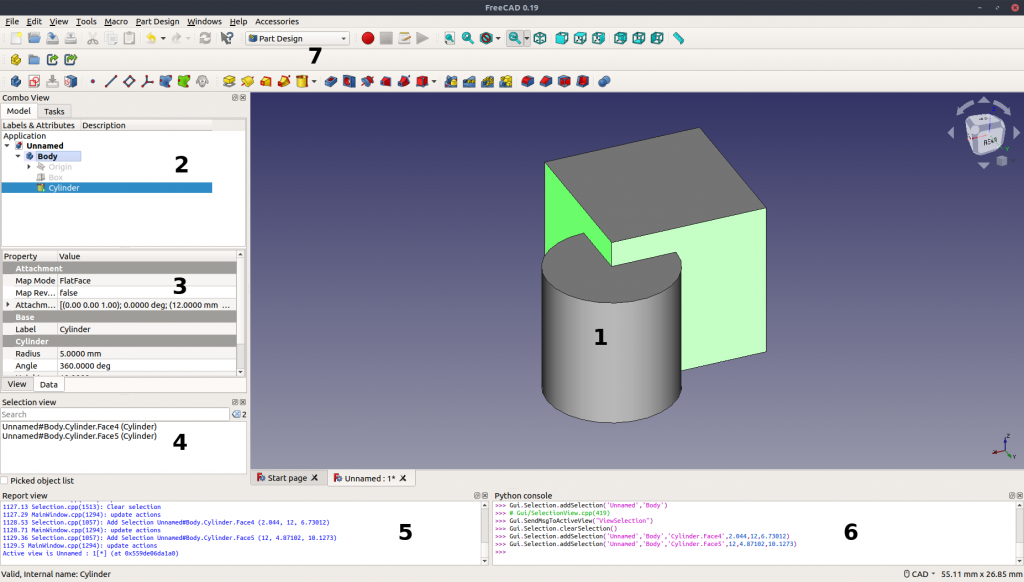

b) FreeCAD: It is a general-purpose and open-source 3D parametric design free software, widely used by many amateurs and advanced users. The parametric component makes editing as easy as pie, you can regulate your models at your will. Best for precise demands, such as designing mechanical engineering, electrical engineering, and architectural objects.

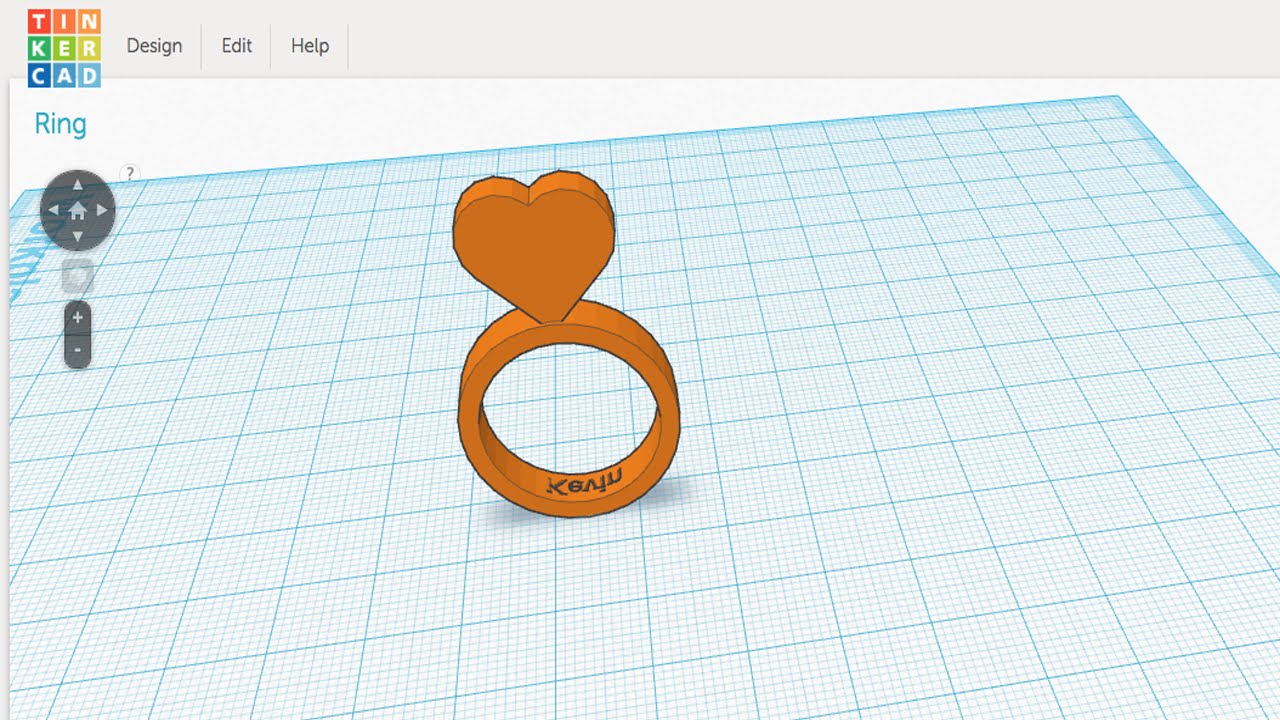

c) Tinkercad: It is free software, very suitable for beginners, for it has lots of tutorials and guides to help everyone to create 3D printing models. It owns millions of files so that you could choose whatever shapes you want and design for them. You can even print your ideal object at home after you press a button, for it has a cooperation with a 3D printing company that provides 3D printing services.

d) Blender: It is intended for amateurs and advanced users, not need payment. Open source and feature-rich are the best advantages of it. Although it was originally used for 3D animation, it is also utilized in sculpting, simulation, rendering, motion tracking, and video editing nowadays. If you want to create organic shapes, such as humans, animals, or monsters, Blender is one of the best options for you without any doubt!

E) 3D Slash: It is free for the web version, $24 per year for the premium license, and $240 per year for the commercial license, adapted to beginners and amateurs. You could slash 3D blocks o build your desired models. 3D Slash also provides logo design and 3D text function. What’s more, you can also use it with a VR helmet. The blockish style may limit people's design to some degree, however, its modeling speed is very fast than other most software.

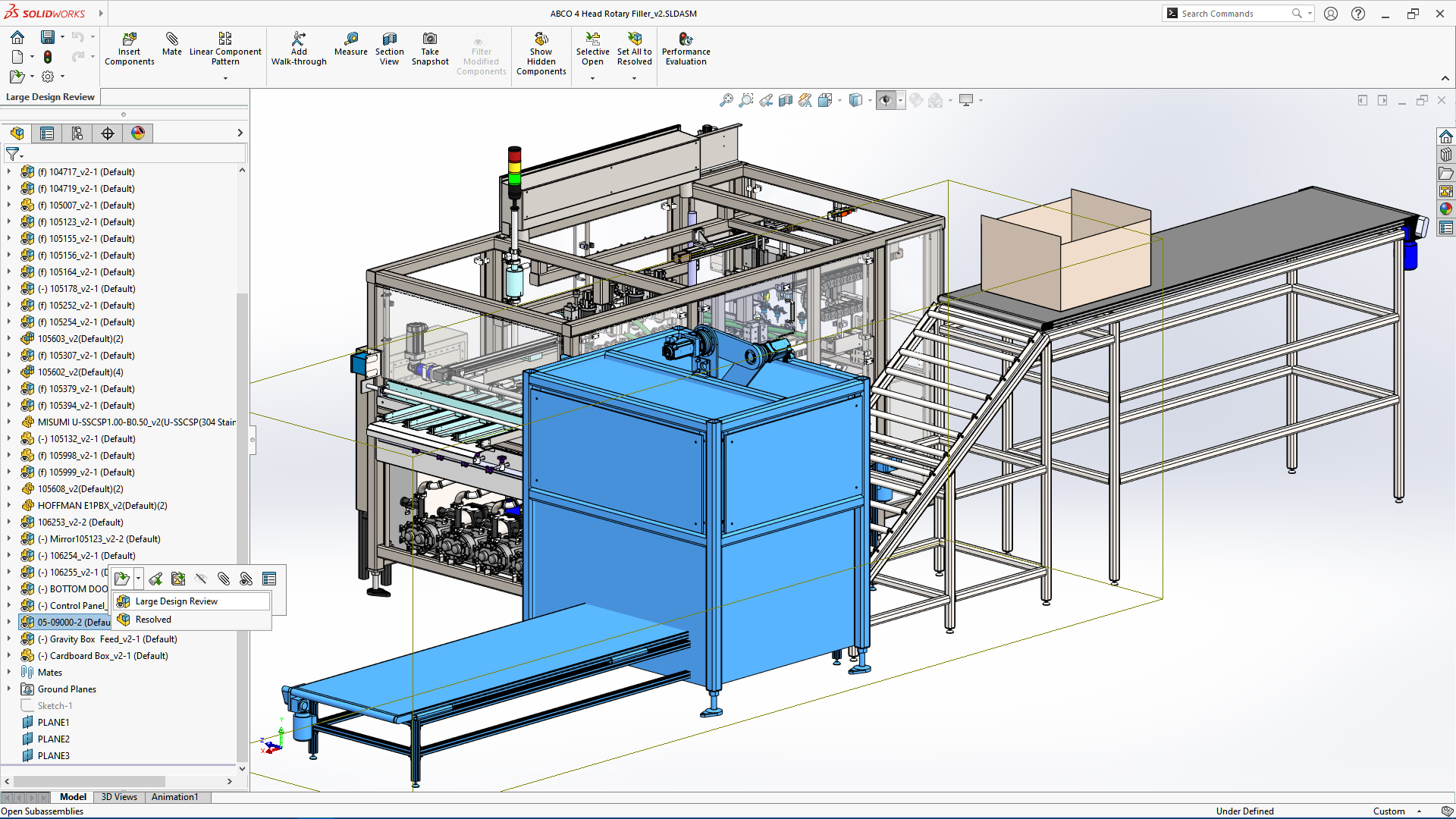

f) SolidWorks: It cost $1,295 per year, or $3,995 for a Perpetual license, intended for amateurs and professionals. SolidWorks is a powerful editing tree and tool for manufacturing, assemblies, simulation, cost estimates, CAM, and 3D printing. It has many advanced functions, such as design validation tools and reverse engineering. Solidworks provides three distinct packages, you could download one depending on what you need. Solidworks tend to industrial design. It uses a system of NURBS that creates averages of the edges to produce fantastically detailed curvatures. It makes resize become easier for it chooses dimensional sketching.

2. Slicing Software

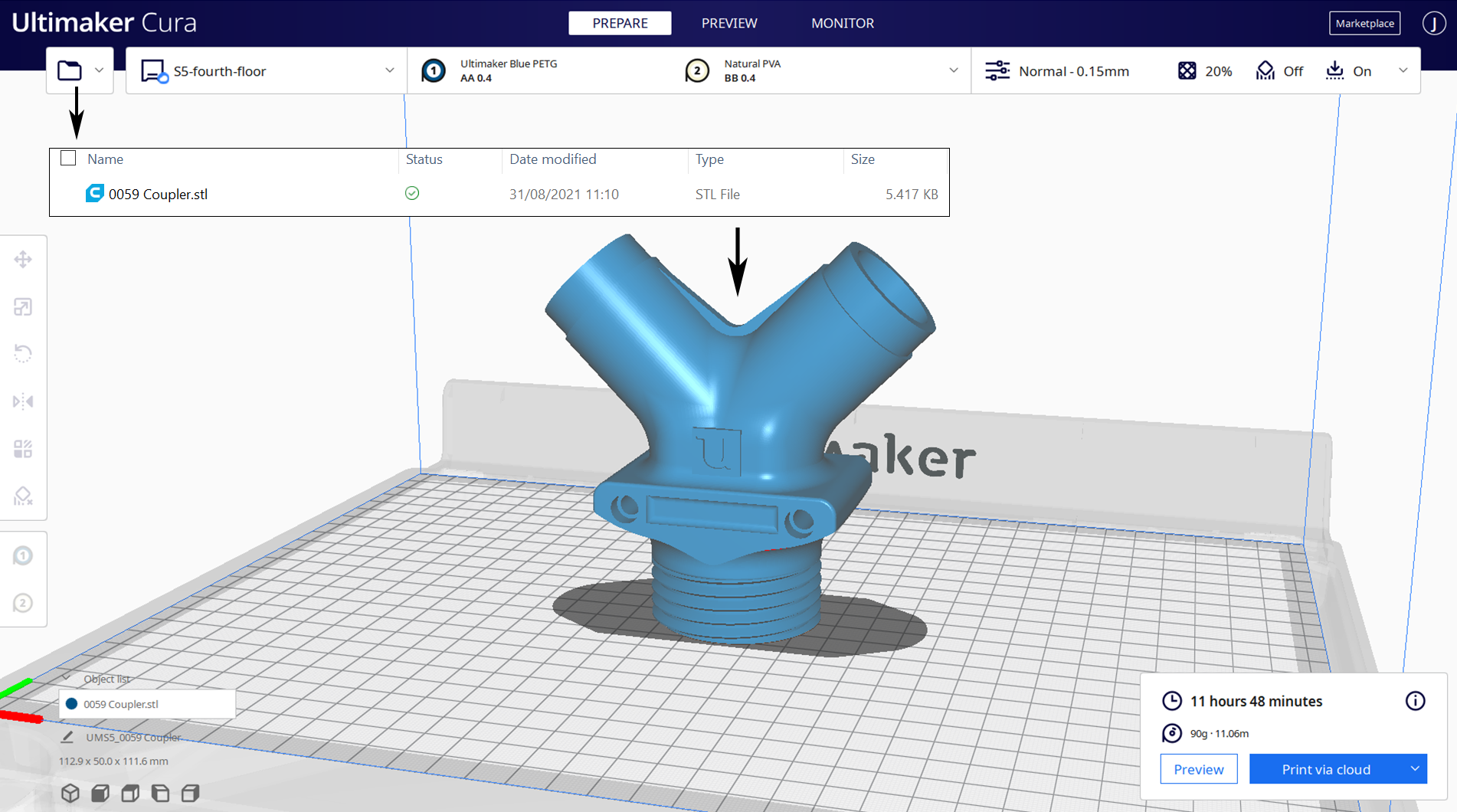

a) Ultimaker Cura: It is an open-source slicing software created by Ultimaker. It can be easily extended through a plugin system, for which plenty of handy plugins are available. You can also easily download others’ profiles. You could switch over to “Advanced”, “Expert”, or “All” to get more settings. Cura offers users 400 settings to tweak models and get the best achievement.

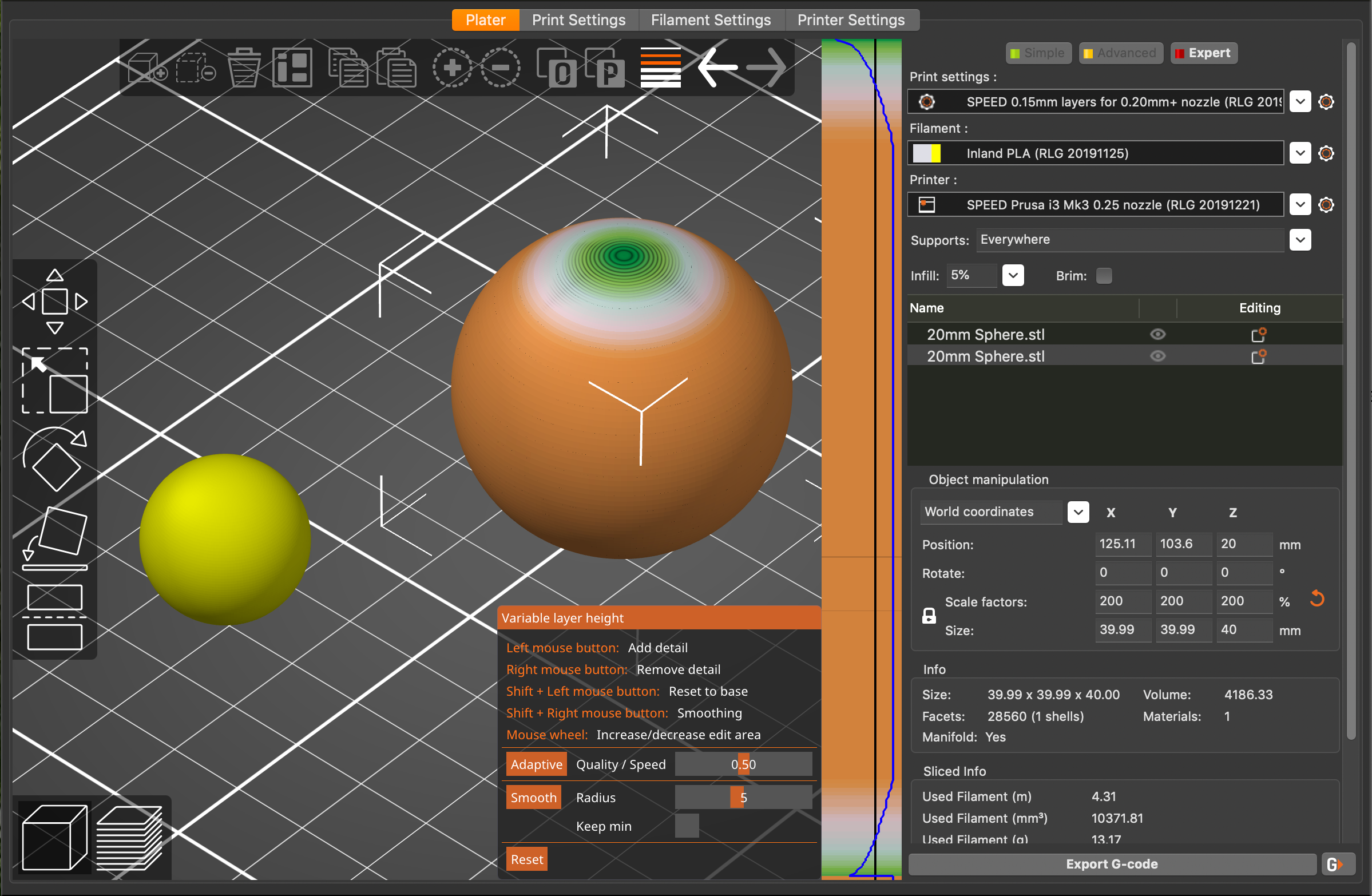

b) PrusaSlicer: It originated in Slic3r. And it maintains most of the original features and even accepts Slic3r configuration bundles when importing profiles. PrusaSlicer not only works with an FDM printer but also an SLA printer. Besides, it adds some critical characteristics, including customizable support structures, multi-material support, and smooth variable layer height functions. Lastly, it is also updated regularly which means you could get well assistance from it.

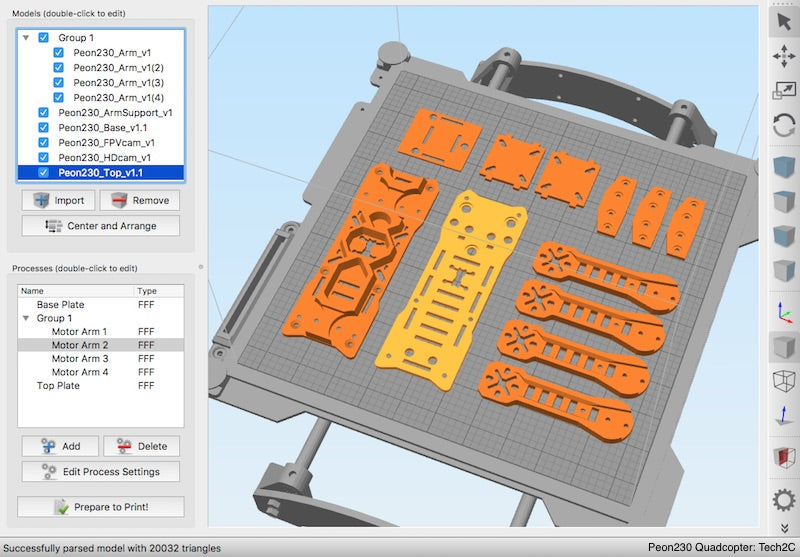

c) Simplify3D: It’s an extremely powerful slicing tool that helps you improve your printing quality. Simplify3D not only does slice your CAD into layers but also corrects problems with your models and allows you to preview the ending results, helping to further identify other questions. Advanced users need to consider whether its features are worth paying for.

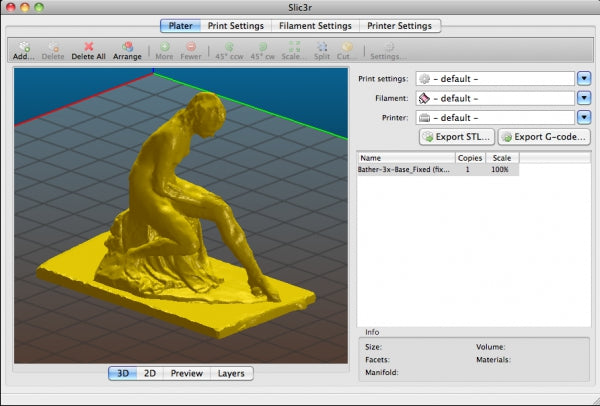

d) Slic3r: It is one of the most widely utilized 3D printing software, with real-time incremental slicing, and 3D preview functions. The incremental real-time slicing can store your progress when you change a setting and only recalculate the G-code. The end result is a quick and precise slicing program.

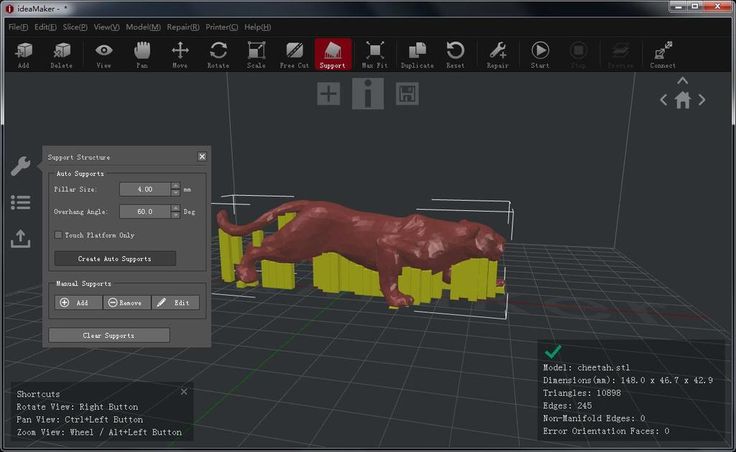

e) IdeaMaker: This free slicer is developed by Raise3D. Team members can share print profiles with this software. Automatically placement and manually placement are both supported. The adaptive layer height tool allows this software to adjust layer height depending on the extent of detail in the model, maximizing printing efficiency. It also supports remote monitoring and control.

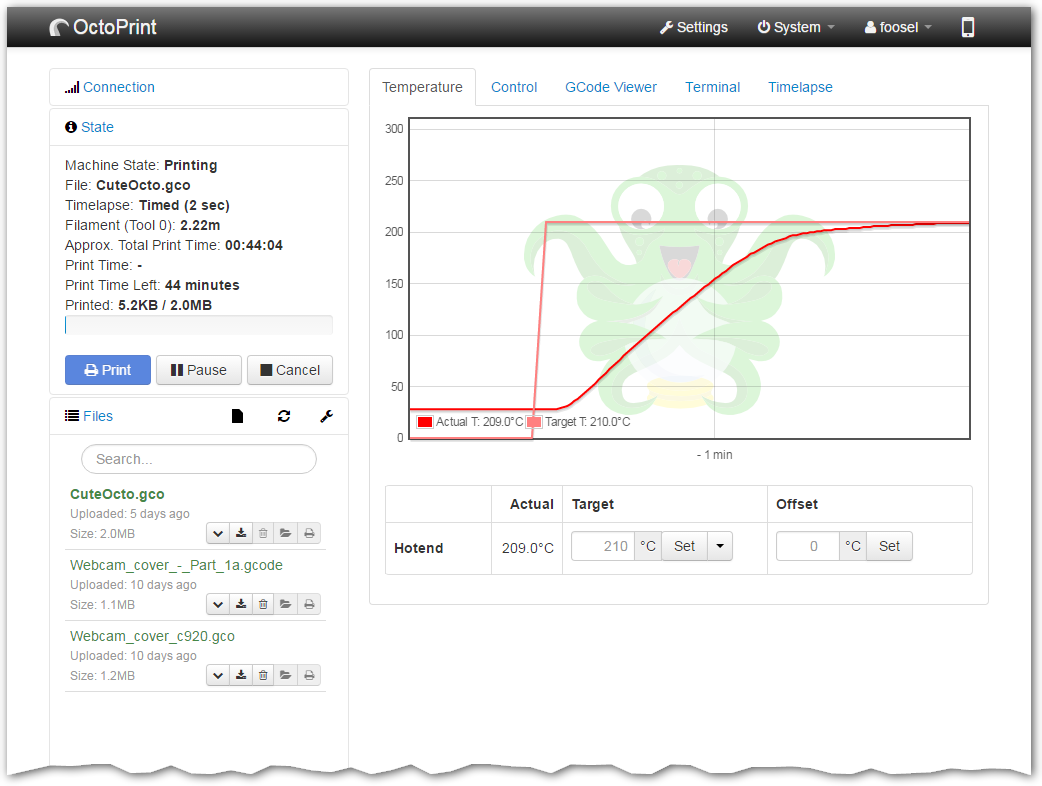

f) OctoPrint: It is a free open-source web interface, created by Gina Häußge. It’s compatible with most 3D printers and allows users to monitor and control their printers. Apart from this, users can use plugins to track their printing statistics and receive push notifications on job progress. On one side, OctoPrint accepts G-code from virtually all slicer software and incorporates a gCodeVisualizer that allows you to preview files before and during 3D printing. On the other side, you can directly slice the STLs files in OctoPrint itself.

Knowing the introductions of these modeling and slicing software, let us remind you of some recommendations when you print your favorite stuff with them.

4. The Dos and Don'ts

a) Consider a right wall thickness of the distance between one surface of a 3D model and its opposite surface. But why it is important? Because one of the most common causes of printing failure is wall thickness. When the wall is too thin, it may cause your design unprintable or fragile. If it's too thick, it will probably generate too much internal stress and lead to model fracturing or breaking. Therefore, you need to set the right wall thickness, which is determined by the material and size of the object. Below is a list of the minimum wall thickness for the most popularly used 3D printing materials which you could take a note of.

PLA -- 1.2mm

ABS -- 1.5mm

Nylon -- 1.5mm

Resin -- 1mm or up

Brass -- 0.6mm - 0.8mm

Aluminium -- 1mm

Silver -- 0.6mm - 1mm

Gold -- 0.8mm

Titanium -- 0.5mm

TPU -- 1.5mm

b) Remember the support structure. During the 3D printing, if you want to build a model whose dangling angle is over 45°, don't forget to add support parts when you are slicing a model. However, these parts may leave ugly traces on your 3D printing models. So you could try to avoid the surpassing 45°dangling issue.

c) Pay attention to the shape and size of the model. If your model's bottom is round or covers less area, the bed adhesion is much lower than those models with flat and wide bottoms. So you need to consider the contact area between the object and the work platform. Beyond that, you should adjust the correct dimension for your model, using a caliper to measure the length, width, and height.

d) Know your printer's strengths and weaknesses. FDM 3D printer is best suited for creating industrial products, while LCD 3D printer could better print personal design. Comprehend your printer, and select a suitable software, and you will get closer to your successful printing works.

Hope this article will give you an idea of how to choose modeling software and slicing software.

Where Can I Get more Information?

3D printers are hot selling around the world. Here are the BIQU Community, and Download Center, where you can search about 3D printers' news or problems solution. If you have any questions, welcome to submit a request to our official website, we will soon settle your problem.

Community & Free 3D Model Files https://biqu3d.com/pages/community

Download the Firmware File https://biqu3d.com/pages/download

Submit a Request https://biqu3d.com/pages/submit-a-ticket

Now there are some general tips for you!

1) You could ask for some advice from a person whom you know, with a fund of professional 3D printer knowledge.

2) If you want to purchase BIQU products, welcome to view BIQU Store!

3) There are some labs, workshops, and maker spaces, where 3D printers are available for trial.

4) You should choose the fittest 3D printer on your own eventually. Considering your demands, work environments, and finances.

5) Whichever company or products you would like to select, please remember to know their sales service and technology support, and even the quality of the accessories and filaments, for they may be an expensive payment.

What's more

If you would like to learn more about the technique and trend of 3D printing and get first-hand information about our new arrivals or discount, you could subscribe to our newsletter!