How much does a 3D printer cost?

If you are a recruit entering the 3D printing world, you may be confused about how much should I pay for a 3D printer, and other costs on its relevant accessories, or upkeep. Don't worry, this article will comprehensively analyze the 3D printing cost, and help you choose your 3D printer, averting dropping into the consumption catch.

Different Types of 3D Printers

| Type of Printer | Price Range |

|---|---|

| Entry Level 3D Printer | $100 – $400 |

| Hobbyist 3D Printer | $400 – $1,500 |

| Enthusiast 3D Printer | $1500 – $4,000 |

| Professional 3D printer | $4,000 - $10,000 |

| Industrial 3D printer | $10,000+ |

1. Entry-Level 3D Printer ($100 – $400)

The entry-level 3D Printers are very nice for novices and are widely used to create small toys, consuming low-temperature filament, for example, PLA. But they will take you a lot of time to assemble, calibrate and level before you use them. And usually, they can only print objects of around 3-4″in each dimension (height, length, and width). Sometimes they are very noisy and slow to print. Anyway, you are still easy to learn how to print, and maybe a magic key for you to open the 3D printing world.

2. Hobbyist 3D Printer ($400 – $1,500)

Printers in this category are more capable. they have larger printing sizes, usually up to 5-6″ in each dimension. And they have a powerful motherboard and control chip to improve printing quality. What's more, they support various materials, such as PLA, TPU, PETG, ABS, Nylon, and so on. However, you may invest some time, financial, and effort to upgrade or calibrate kits. Due to they have a high DIY function, they are more suitable who have already known 3D printers. Plus, they are also appropriate for printing garage kits or action kits.

3. Enthusiast 3D Printer ($1500 – $4,000)

The Enthusiast 3D Printers are vigorous growth, usually designed with semi-enclosed and fully enclosed designs. And their printing size can reach 8-12″ in each dimension. Besides, their hardware and software functions are more versatile, which can highly improve your printing speed and quality. Their accessories and materials are also very high-quality and durable. However, you still need to maintain and update your accessories on a regular time.

4. Professional 3D printer ($4,000 - $10,000)

This type of 3D printer could print large size models, about 12″ in all dimensions. And they can use various materials, such as ABS, Nylon, CFRP, PC, and so on. Certainly, a professional 3D printer will do an excellent job in 3D printing, no matter in printing speed or quality. And before this type of 3D printer, maybe sacrifice one of them. They can use in many areas, such as in robotics clubs, universities teaching, and businesses. Nonetheless, a high price may stock your purchasing willingness. Only recommend you purchase them for specialized needs.

5. Industrial 3D printer ($10,000+)

Professional enterprises or large-scale manufacturers usually utilize this type of Industrial 3D Printer. The SLS 3D printer is the most common, and FDM and LCD 3D printers are also included. There are more material options for it, such as PLA, ABS, PETG, PLA-based composites, nylon, aluminum, titanium, cement, resin, and so on. Besides, it can automatically regulate temperature when it works, no need for frequent adjustment by hand. Without a doubt, an industrial 3D printer has higher printing efficiency. However, you should also consider other costs, there are no small sums. Firstly, if you use a large machine, which means you should pay more water and electric charge, around $150 for extra money. Secondly, the repair is a tough problem for its structure is not as simple as the table 3D printer's. So you should ask for the assistance of professional maintenance technicians for help, and it may cost from $100 to $3,000. In a word, these bits and pieces of long-term costs need to be taken into account.

There is a misunderstanding here, not the more expensive 3D printer is better. You need to consider your models, consumables costs, maintenance costs, upgrade costs, etc., to choose the most suitable 3D printer for yourself. If you want to know more information, you could visit our another blog: What is 3D Printing, and How to Choose a 3D Printer? Next, we will recommend you an Entry-Level 3D Printer and an Enthusiast 3D Printer, which you could take into consideration.

Recommend You Entry-Level 3D Printer BIQU B1 3D Printer (FDM) $255.99

a) Large printing size: It has a larger printing size than other entry-level 3D printers in the market, about 9*9*11″, satisfying your sorts of printing needs.

b) Silent running: Carry TMC2225 V1.0 TMC driver, with silent and stable. You can print your creations in a quiet environment. Don’t worry about the noisy sound will disturb your family or neighbor anymore!

c) Filament detection: The printing will auto-stop when filament runs out and will continue to work after reloading the materials.

d) Power loss recovery: It can readily resume printing after unexpected power outages, and make sure your printing progress.

Recommend You Enthusiast 3D Printer BIQU PIXEL L 3D Printer (LCD) $899

a) Flip cover design: Designed with a flip cover and transparent hood, which can filter the UV light when leave unused, and clearly monitor the printing process when used. Plus, it doesn't need to occupy too much space.

b) Large printing size: It has a large modeling area, around 8*5*9″that you will have more printing options.

c) Free leveling: It has a precise platform structure design, no need for manual leveling, you can assemble and directly use it.

d) Heated resin vat: Unique heated vat ensures the fluidity of resin at low ambient temperature, even in winter, and improves your reflux speed, printing speed, printing quality, and molding rate.

These two types of 3D printers are very capable and cost-effective. Wish they will bring you into the beauteous world of 3D printing. Please pay attention, the cost of a 3D printer is only a fraction of the cost of 3D printing. Next, we will discuss other long-term bills related to 3D printing.

Long-Term Payment on 3D Printing

a) Model complexity

Setting a clear target of what you want to print is very crucial. If you plan to design a complex model, you need to add some support structures, and choose a suitable 3D printer and filament, and so on. Please note that the support structures will consume more materials. So the objects determine the cost of 3D printing to a great extent. And the cost of a 3D printer is from $100 to $10,000+.

b) Modeling Software and Slicing Software

There are some free modeling software and slicing software, so you may don't have to pay for this section. If you want to choose a charged one, here is a price reference. For example, modeling software, "SolidWorks" costs $1,295 per year. Want to know more about the software information, you could visit another Blog: Tips for Choosing 3D Modeling and Slicing Software. And please pay attention, the slicing software of FDM 3D printer and LCD 3D printer is different, so you should choose the suitable one for your 3D printers.

c) Material

There are most commonly used materials, such as ABS and PLA in FDM 3D printers, or resin in LCD 3D printers, with relatively low prices and good performance. These filaments cost between $15 to $60 per kg, usually used in FDM 3D printers. If you want to use a resin 3D printer, it may cost $ 30 to $180 per liter. It's hard to say how exactly the materials will cost in a year.

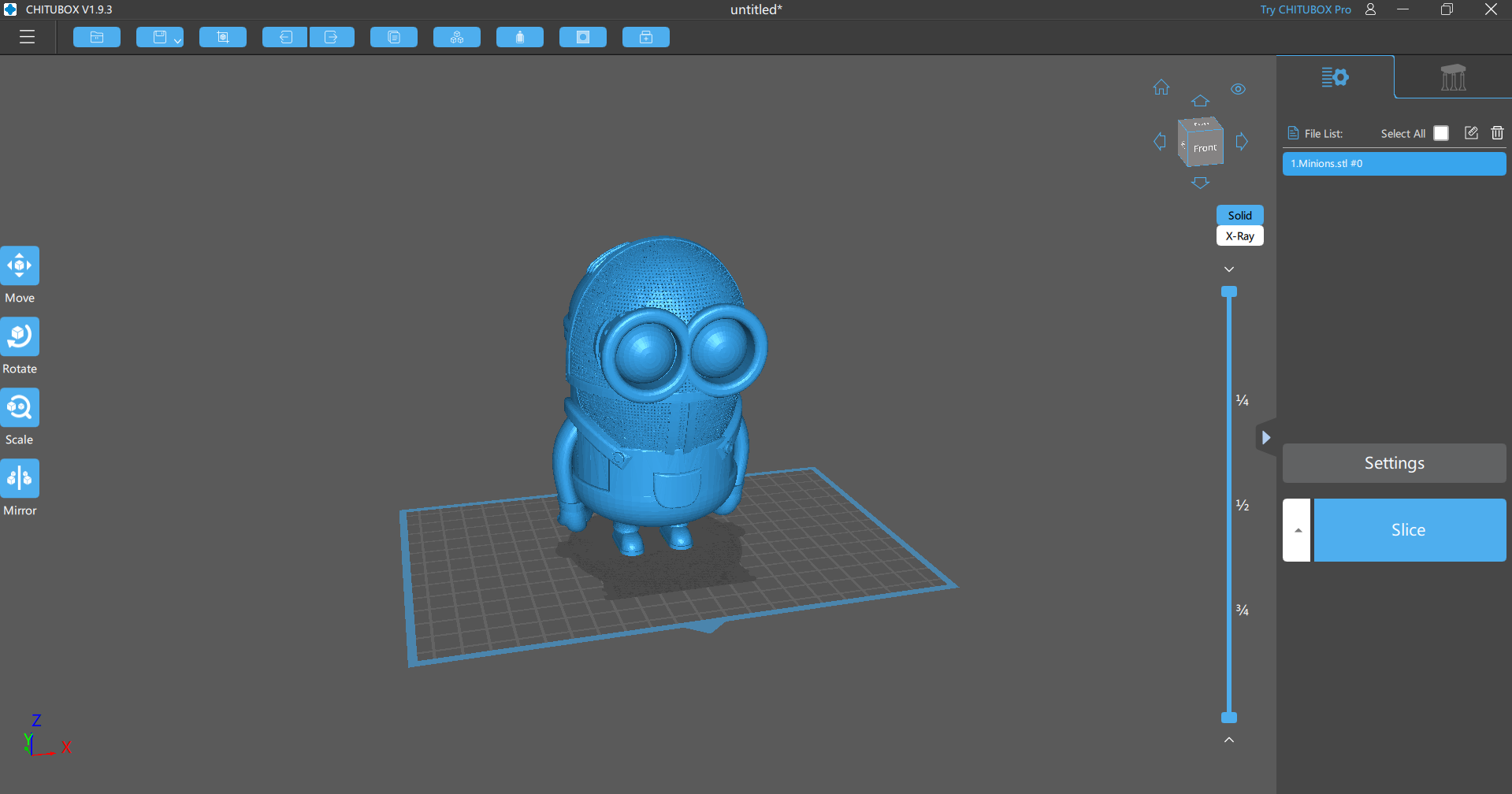

Using an FDM 3D printer, let's take this minion as an example. This model is 79.2*75.5*122.9mm (roughly 3.1*3.0*4.8″). 1KG PLA filament may print 6 Minions (filled density is 22%). If you print such size of model every time, then you will spend 15 hours once printing, and print 3 times a week, and 144 times a year. You may cost 24 kg filament in a year, cost $360 at least.

While using an LCD 3D printer, let's take this minion as an example. This model is 79.2*75.5*122.9mm (roughly 3.1*3.0*4.8″). 1-liter resin filament may print 3 minions. (wall thickness 2mm) If you print such size of model every time and spend 7 hours once printing, 3 times a week, and 144 times a year. You may cost 7 liters of resin in a year, which cost $1440 at least.

d) Post-processing

When you finish your printing, you should do some polish and print. Some odds and ends could finish this part.

If you use an FDM 3D printer, you may need a 3D Printer Tool Kit (average cost of $30), and an Acrylic paint set (usually cost $40 to $60). If you use two sets of paint, roughly every year's expenditure is $130 in a year (average cost).

If you use an LCD 3D printer, you may need a 3D Printer Tool Kit (average cost $30), an Acrylic color paint set (some famous brands, such as Warhammer, Vallejo, etc. From $38 to $165), UV curving light (selling from $20 to $2800, average $35) to do the last solidification, or you could also expose it under the sunlight ultraviolet to realize the effect. Normally, you may consume 2 sets of color paint (120 Pieces), and even more. In this part, we could roughly cost $267 per year (average price). Of course, this price is unstable, because it depends on your painting needs.

e) Replacement Part and Upgraded Kit

We all know 3D printers need to upgrade for a fixed period, and it will help you improve your printing quality and speed.

The upgraded kit price of the FDM 3D printer is from $10 to $500, depending on a part, or a set kit. Typically the extruder (cost $83) will change 2 or 3 times in a year, while the motherboard (cost $38), display (cost $47), and driver board (cost $13) will change 1 time in a year. So we can approximately regard the cost of this part as about $681 per year.

On the other hand, when you utilize an LCD 3D printer, you may change the release liner (cost $10 to $20), and display (cost around $20). The release film is easily worn during use and often needs to be replaced in one or two months. While the screen may be changed 1 time in one or two years, even longer time. The estimated consumer price is $80 per year.

The First Year Total payment

How much does 3D printing cost? Take the BIQU B1 3D printer and Pixel L 3D printers as examples. And plus filament cost, upgrade kits, modeling software, and polishing, We can get a rough number. If you are a 3D printer hobbyist, usually print 3 times a week. When you use an FDM 3D printer, you may at least cost $2722 in the first year, or $227 per month, or $7 per day. When you use an LCD 3D printer, you may at least cost $4011 in the first year, $334 per month, or $11 per day.

In the second year and beyond, you may cost around $2466 using FDM 3D Printer and about $3112 using LCD 3D Printer. (Later you don't need to pay for the 3D printer machine again, unless you want to change it, and just pay for other parts.)

3D Printing Service (Replacement)

If you don't usually print, you could choose this printing service. Let's take the minions, which size is 79.2*75.5*122.9mm (roughly 3.1*3.0*4.8″) for example again. It may cost about $90 to print one. And add some color and polishment, it will cost $98. If you print 144 such models per year, you will totally cost $12960 per year (including printing and polishing). If you are enthusiastic about 3D printing, trust me, possessing a 3D printer and printing on your own, you will get incredible fun creating!

Summary

Where there is pay, there is gain. If you love 3D printing, please rationally consume for it, according to your financial situation. After a prolonged endeavor, you will gain the one and only artwork, which is created on your own. That sounds amazing, isn't it?

Where Can I Get more Information?

3D printers are hot selling around the world. Here are the BIQU Community, and Download Center, where you can search about 3D printers' news or problems solution. If you have any questions, welcome to submit a request to our official website, we will soon settle your problem.

Community & Free 3D Model Files https://biqu3d.com/pages/community

Download the Firmware File https://biqu3d.com/pages/download

Submit a Request https://biqu3d.com/pages/submit-a-ticket

Now there are some general tips for you!

1) You could ask for some advice from a person whom you know, with a fund of professional 3D printer knowledge.

2) If you want to purchase BIQU products, welcome to view BIQU Store!

3) There are some labs, workshops, and maker spaces, where 3D printers are available for trial.

4) You should choose the fittest 3D printer on your own eventually. Considering your demands, work environments, and finances.

5) Whichever company or products you would like to select, please remember to know their sales service and technology support, and even the quality of the accessories and filaments, for they may be an expensive payment.

What's more

If you would like to learn more about the technique and trend of 3D printing and get first-hand information about our new arrivals or discount, you could subscribe to our newsletter!