The Most Important Parts of 3D Printer

On one hand, the best way to get into the 3D printing world is to learn about the main parts of a 3D printer. On the other hand, knowing well 3D printer parts is also the best precondition to DIY printers themselves for 3D printing hobbyists. What's more, you may further know the working principles of a 3D printer, and settle down the frequent problems. You could also take this article as a reference for your purchasing list.

1. Mainboard

2. Extruder

3. Expand Board

4. Driver Board

5. Display

6. Heat Bed

7. Upgrade Kits

Definition

The Mainboard, (also called the motherboard, or control board) in a 3D printer is the main printed circuit board (PCB), which is consisted of hundreds or thousands of integrated circuits and electronic components. It holds and allows communication between crucial electronic components of a system, such as the central processing unit (CPU) and resistor, and provides connectors for other peripherals (which are not originally embraced in the mainboard, and need some ports and wires to connect to the mainboard), such as the USB flash disk, and cooling fans. And the peripherals are also called terminals.

In simple terms, a mainboard concludes with one PCB board and a great number of electronic components. The electronic components (also called ports or interfaces) are soldered on the PCB and surrounded by lots of pins, resistors, capacitances, and inductances. If the CPU is the brain of a 3D printer, the motherboard can be seen as the backbone, for it keeps the device running and connects all the electronic components, making the 3D printer usable. (P.S. There are still many minor chips in the mainboard.)

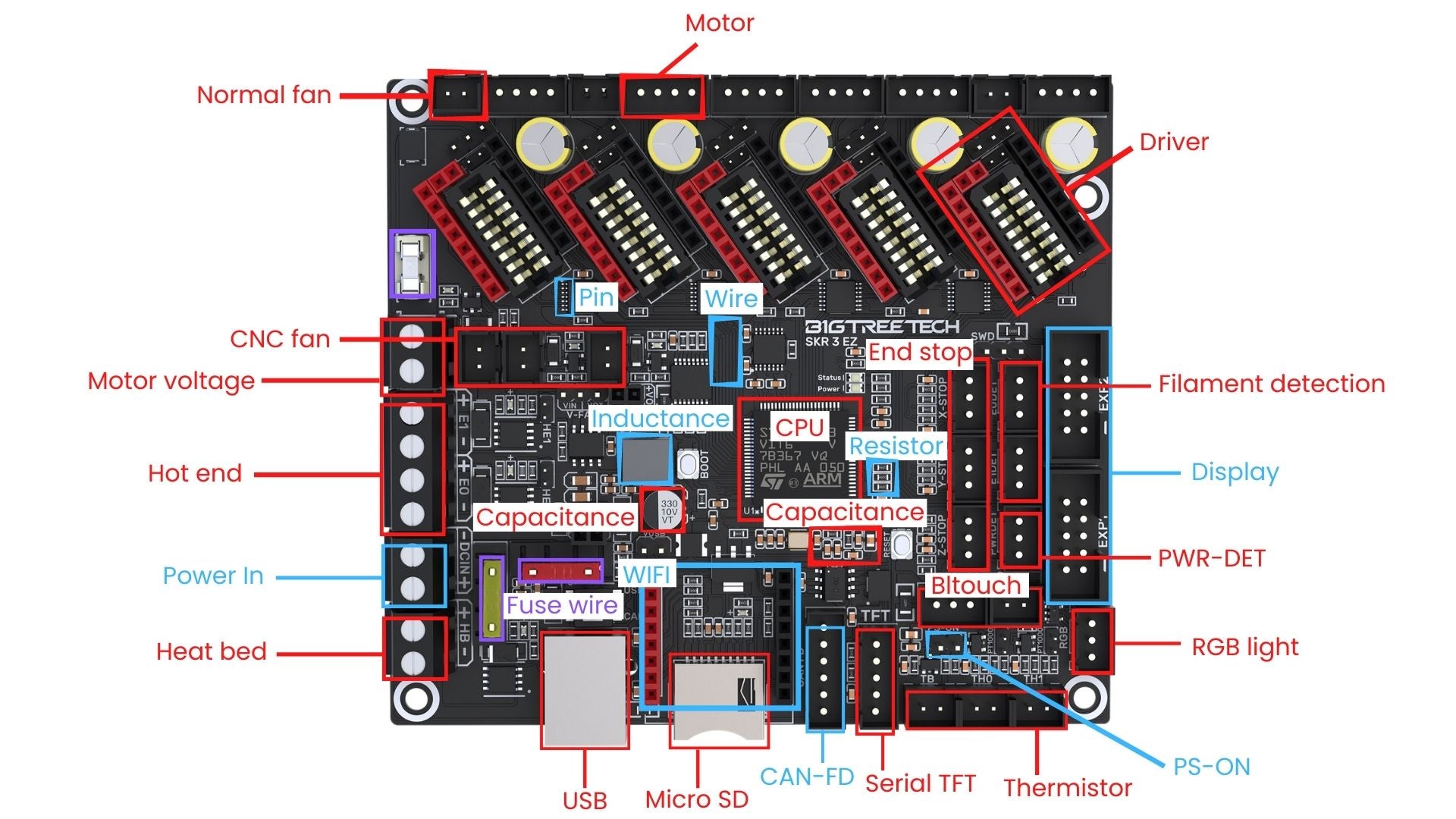

You may wonder what exactly it contains? Please look at the picture below, let me tell you pieces of detailed information!

Components

[1] Normal fan: Fans are used to cool off the main circuits of the printer, such as the central processing unit and motor drivers. Keeping these components cool is essential for their long life span. Usually rated voltage is 5V, 12V, or 24V.

[2] CNC fan: A fan of computer numerical control, which you could regulate the voltage, from 5V, 12V, or 24V. Its usage scenario is as same as the normal fan. You can use this function through a DC mode, which should be purchased additionally. When you instruct your mainboard to control this part, it first goes through to the CNC FAN Mosfet, then sends it to the CAN fan.

[P.S. Mosfet: is a type of insulated-gate field-effect transistor that is fabricated by the controlled oxidation of a semiconductor, typically silicon.]

[3] Motor voltage: Motor voltage is the pressure from the machine power source that pushes a current through a circuit. Measured as the electrical potential between two points and rated in volts (V). Typically motor voltage range is from 12V to 48V. Connects to the motors of the X-axis, Y-axis, Z-axis, and extruders.

[4] Hot end: The hot end is the component of a 3D printer that melts the filament for extrusion. It also contains Hot End Mosfet.

[5] Power In: It is a power input port, which connects to the power supply. Usually, the input voltage range is from 12V to 24V.

[6] Heat bed: A heat bed is an aluminum base, also called aluminum PCB, an indispensable module for a 3D printer. On the one hand, by heating to a certain temperature, the model can firmly adhere to the platform, usually collaborated with insulating cotton to keep warm. On the other hand, the models could be removed conveniently, especially when you print complicated models that stick to the platform tightly. Then you may need a heat bed to take off the model easily. This part also contains Heat Bed Mosfet.

[7] Motor: Usually refers to a stepper motor. Some motors are utilized to move the extruder or the building platform through and are installed on the X, Y, and Z-axis. While some motors are used to push the filament into the extruder.

[8] Driver: It is important to distinguish between motors and drives. A drive is an electronic device that harnesses and controls the electrical energy sent to the motor. While a motor is a mechanical or electrical device that generates the rotational or linear force used to power a machine. In a word, the motor governs the printing platform and extruders, and the driver controls the motor. And the drive port capacitances are used for supplying the electricity to the drivers. (the round patterns in the picture)

[9] Pin: The pins are those pin headers on the motherboard or the specially defined pins marked on the PIN diagram.

[10] Wire: There are thousands of wires connected to the mainboard, some are invisible, and are also called integrated circuits.

[11] Inductance: It is the tendency of an electrical conductor to oppose a change in the electric current flowing through it.

[12] Capacitance: Capacitance is the ratio of the amount of electric charge stored on a conductor to a difference in electric potential.

[13] WIFI: It is used to remote control a 3D printer, initiating or pausing. Plus, Klipper firmware needs to use the WIFI function, either.

[14] Fuse wire: Its essential component is a metal wire or strip. When the current surpasses the rated current of the fuse wire, the fuse wire will be fused, leading the mainboard cannot be powered on. It is an electrical safety device that operates to provide over-current protection of an electrical circuit and must be replaced once fused.

[15] USB: Used for inserting the USB flash disk, which stores your printing model files. It leaves vacancies outside of the 3D printer, easy to plug in or out.

[16] Micro SD: Used to update your firmware, and also reserve your printing model files. It leaves vacancies outside of the 3D printer, easy to plug in or out.

[17] CPU: A central processing unit (CPU) is the electronic circuitry that executes instructions comprising a 3D printer program, concluding basic arithmetic, logic, controlling, and input/output (I/O) operations. There are four steps in its work. First, fetch the data and instructions from RAM. Second, decode the instruction, and translate it into a machine language. Third, execute the commands, and control the device. Last, store the output information. A single central processing unit only executes one command at a time. So there derives dual-core processors, quad-core processors, octa-core processors, and so on to deal with multiple and complicated tasks. Because the CPU must operate continuously, causing much load on the CPU, it often heats up. To avoid the heating problems, suggest installing a cooling fan on the CPU.

[18] End stop: Endstop switches, also known as mechanical end stops, are contact-based manual switches (or buttons) that determine when an object is at the end of its axis path. When the switch is touched by an object, it signals to the mainboard that the object is at the end of the axis path.

[19] Resistor: It is a passive two-terminal electrical component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, divide voltages, bias active elements, and terminate transmission lines, among other uses.

[20] CAN-FD: Used for CAN communication, eliminating many complex wires connecting problems on one hand; on the other hand, having a high anti-interference performance, preventing other electronic-signals disturbance.

[21] Bltouch: It is an auto-leveling sensor for 3D printers that can precisely measure the tilt of the printing platform. This sensor can work on any type of bed surface, such as metal, glass, wood, and so on.

[22] PS-ON: It is an automatic shut-down module. It will automatically turn off your 3D printer when the printing is finished.

[23] Serial TFT: Specially used to connect to BIQU TFT series' display.

[24] Thermistor: It is a very accurate sensor for measuring the heat rod's temperature. Then send the temperature data to the mainboard, which finally shows on the display.

[25] Filament detection: This sensor can detect when your printer has run out of filament, and remind your mainboard.

[26] Display: Used to connect to the display, which you could control the printing process.

[27] PWR-DET: This power detection module port can realize resuming printing while power off, ensuring your printing schedule.

[28] RGB light: There are three main lights, red, green, and blue, and could also create millions of different colors of light from these primary lights. Used to decorate your 3D printer.

Knowing the definition and composition of the mainboard, you may want to know its location. It is installed on the bottom of a 3D printer. Inside a 3D printer, there is a mainboard, the circuit board of display, machine power supply, and adapter plate. In some cases, there may exist an expansion board, also called a functional board, to achieve your various printing requirements. (P.S. Every printer has a specialized adapter plate, which integrates numerous wires into one or two wires and separately again links to the extruder, filament detection, and heat bed.)

Working Principle

When you turn your 3D printer on, 220V family voltage transforms into 24V or 12V direct voltage through the switching power supply and provides power to the mainboard. When the mainboard initiates, the electricity goes through the fuse wire and is transmitted to every component, such as the motor port, CPU, and every Mosfet.

Function

Mainboard has two main functions. One is to provide connectors for other peripherals. Another is to control all the parts of the 3D printer, such as the extruder, heat bed, and so on.

Service Life

In general, you may change your mainboard every one year, because of damage problems or upgrade needs. And please remember to choose the one which is adaptive to your 3D printer. This is the same rule in changing other accessories.

Price

The price is usually from $72 - $299, on average $97. You could choose one for your needs.

Definition

An extruder is the part of the 3D printer that is responsible for pushing the filament to the hot end and melting it, then extruding it on the printing platform to build a model. The extruder can be divided into the Bowden Extruder and the Direct Extruder.

1) Bowden Extruder

A Bowden extruder has consisted of a pedestal, handle, screws, U groove, spring, pneumatic motor head, silicone sleeve, tube connector, and extruding gear. (Usually, the packing list also concludes TL-smoother, stepper motor vibration damper, PTFE tube.) The extruder is installed on the motor, and separated from the printing head. A Teflon tube links these two parts. Sometimes, people call the extruding part a cold end, while calling the heating part a hot end. And the whole part is called the extrusion system. The function of the Bowden Extruder is to push and transport the filament into the PTFE tube, and finally, reach the hot end to be melted.

2) Direct Extruder

The direct extruder assembles a motor, extruding gear, and hot end, installed on the X-axis. Detail compositions please look at the following picture. The usage of a direct extruder is to send the filament into a hot end to be melted and extrude it through a nozzle to form a model.

BIQU H2 500℃ Extruder Structure

Seeing now, you may wonder which one should I choose? What are their advantages and shortcomings of them? Please go ahead to explore them!

Sorts

Bowden Extruder

Direct Extruder

Advantages

a) The print head is light in weight, small in inertia, and more accurate in movement and positioning.

b) The moving speed of the printing head can reach 200-300mm/s, so its printing speed could also be very fast.

c) The nozzle and extruder are divided and easy to be maintained.

a) The control of feeding materials is more accurate, and the retraction is more precise, too.

b) The torque requirements for the extrusion stepper motor are relatively low.

c) Handy for changing the materials.

Shortcomings

a) The feeding distance is long, with high obstruction, asking for a greater torque of the stepper motor that is responsible for extrusion. And the materials in the PTFE tube can't be run out.

b) The filament and Teflon tube have a certain elasticity, and the general pneumatic motor head also has a certain activity space, leading the retraction distance and speed larger, which is not as accurate as of the direct extrusion retraction.

c) It's not convenient to change the material, the filament can't be withdrawn when it is in the feeding tube.

a) The hot end, extruder, stepper motor, cooling fan, etc. are integrated together, which is inconvenient for disassembly and maintenance.

b) The print head is heavy, especially the dual-nozzle printer. The inertia is large when moving, and it is relatively difficult to accelerate and decelerate, which is not as accurate as of the short-range extrusion retraction.

c) The heavier nozzle puts more pressure on the optical axis or guide rail, and it is easy to bend it for a long time. Usually, the nozzle is lower in the middle of the optical axis than on both sides, which makes it difficult to level the platform.

Service Life

In general, you may change your extruder every year, because of damage problems or upgrade needs. And please remember to choose the one which is adaptive to your 3D printer. This is the same rule in changing other accessories.

Price

The price is usually from $10 - $57, on average $20. You could choose one for your needs.

3. Expansion Board / Functional Board

Definition

An expansion board, also called a functional board, is a printed circuit board that you can insert into a 3D printer to give it added capabilities. For example, all of the following are expansion boards:

Filament sensor detection, cloud wireless transmission module, driver expansion module, EEPROM extension module, BL touch sensor, RGB LED light, WIFI module expansion, power module, UPS (Resume Printing While Power Off Module), automatic shutdown module after printing, TL-smoother, mechanical end stop, CNC shield expansion board, temperature detector module.

Service Life

In general, you may change these functional boards every year, because of damage problems or upgrade needs. These part is not necessary, but is very useful, improving your printing experience. And please remember to choose the one which is adaptive to your 3D printer. This is the same rule in changing other accessories.

Price

The price is usually from $10 - $46, on average $29. You could choose one for your needs.

Here we will introduce three expansion boards as the pictures show.

1) WIFI module expansion

It is an expansion board that added a web interface for a 3D printer. Consisted of one PCB board, the main control chip, USB port, EXP cables, USB cable (communicate with a computer), and a series of electronic components, such as capacitances and resistances. It mainly has two functions. The first is to remotely control your 3D printer when you don’t be close to your machine. The second is to freely modify the firmware configuration, eliminating constantly flashing the board when you do significant changes. It can easily backup and restore firmware because it has an ESP8266 module, with 512KB to 4MB flash memory, of which 64KB to 3MB can be used as the file system, and its function is similar to an SD card. Even though you change to another printer, you could easily copy the contents.

2) Filament sensor detction

It is an intelligent filament broken detection expansion board, composed of a filament sensor detection module, set screws, Teflon tube, pneumatic connector, and transducer cable. When the materials are plugged or run out, the machine will automatically prompt and stop working to reduce the accident. Thus you can well monitor your extruder. Any motherboard with a break detection interface can use it. Plus, it supports all 1.75mm materials. The working principle is: After you set an accuracy of 7mm in the firmware, the filament moves 7mm to detect whether the IO has level fluctuation. If there is a change, it is determined that there is no problem.

3) Automatic shutdown module

It consists of the main control chip, resistance, capacitance, relay, Mosfet, terminals, and power module. There are two functions. The first is circuit protection. After connecting the 5V and GND on the motherboard to the module, if there is a 5V short circuit, the module will immediately power off to prevent damage to the motherboard. Second, it can automatically cut off the power after printing, very power-saving and environmental protection. Please note that the bottom of the Ray V1.2 module shall be far away from water, metal, and other conductors. And please don't touch the wire to prevent electric shock when the module is working.

Definition

It is an accessory that drives the motor motion. Some drivers could rotate silently, and achieve the highest efficiency and the best motor torque control. In addition, it is a solution for realizing economically efficient for its high integration, high energy efficiency, and small form factor.

Service Life

In general, you may change the driver boards every year, because of damage problems or upgrade needs. This part is very important and will improve your printing experience. And please remember to choose the one which is adaptive to your 3D printer. This is the same rule in changing other accessories.

Price

The price is usually from $15 - $30, on average $20. You could choose one for your needs.

Definition & Function

It is very common in the market for high-touch screen LCD screens, with rotary knobs. These screens could choose the printer's functions and adjust its settings. Plus, they are also able to show you the remaining printing time and model completion rate. Some printers can achieve remote printing through the WIFI function but also required special firmware, such as Klipper.

Service Life

In general, you may change an LCD screen every year, because of damage problems or upgrade needs. These part is very important and could prolong your 3D printer's life span. And please remember to choose the one which is adaptive to your 3D printer.

Price

The price is usually from $16 - $46, on average $29. You could choose one according to your requirements.

Definition

Actually, a heat bed is an aluminum baseboard, also called an aluminum PCB, an indispensable module for a 3D printer. On the one hand, by heating to a certain temperature, the model can firmly adhere to the platform, usually collaborated with heat insulation cotton to keep warm. On the other hand, the models could be removed conveniently, especially when you print complicated models that stick to the platform tightly, you may need a heat bed to take off the model easily. It is a part of the printing platform.

The printing platform is divided into two kinds. One consists of a spring steel sheet, a soft magnetic slice, an Aluminum baseboard, and heat insulation cotton. Another type of printing platform consists of carbon crystal silicon glass, aluminum base, and heat insulation cotton. Usually use four clamps to fix the surrounding of the glass and base.

P.S.

1) Spring steel sheet: It is essentially a magnetic sticker, which can stick to the Soft magnetic slice, and both of them have a magnetism. It is the top section of a printing platform. You could readily remove the model from this plate, but may warp after using a long time.

2) Soft magnetic slice: It can stick to the aluminum baseboard, a middle part of a platform.

3) Aluminum baseboard: It is a heating table, and can paste with a soft magnetic slice and heat insulation cotton.

4) Heat insulation cotton: It is used to keep warm the model and paste it to the bottom of an aluminum baseboard.

5) Carbon crystal silicon glass: This material could avert the warping problem, but it's not so easy to remove the model.

Service Life

In general, you may change these accessories every year, because of damage problems or upgrade needs. These part is very important and will highly impact your printing quality. And please remember to choose the one which is adaptive to your 3D printer.

Price

The price is usually from $58 - $94, on average $76. You could choose one according to your requirements.

Definition

Upgrade Kits are very important in a 3D printer, and should be changed or updated in a certain period. Usually, they are referring to the axis, screw rods, cables, and so on. There list some upgrade kits you could take as a reference.

Service Life

In general, you may change these upgrade kits every year, because of damage problems or upgrade needs. These part is very important and could prolong your 3D printer's life span. And please remember to choose the one which is adaptive to your 3D printer.

Price

The price is usually from $20 - $394, on average $80. You could choose one according to your requirements.

1) BIQU B1 double Z-axis upgrade kit

The double Z-axis upgrade kit can reduce the wobbling of the X-axis, and ensure the printer runs smoothly. We all know that stability will highly impact the precision of a model. So you can choose this set of axis to improve your printing quality.

2) Hermit Crab

It is a rapid and easy tool changer for extruders, consisting of one Fixed Plate and a tool plate. This tool is clip design, you can readily get them together or separate them. The aluminum body is very strong, flexible, and rust-resistant, giving you a better user experience. There are two versions of it, the Normal version and the CAN version. Their functions are similar. The normal version could support Marlin and Klipper firmware, while the CAN version supports Klipper firmware, and also provides CAN communication, which gets rid of lots of complicated connecting cables.

3) NS0175 Ender-3 Upgrade Dual Z Kit

This Dual Z Kit is easy to assemble, and easy to level, so you don't need to industriously adjust it. The T8 screw rod makes it run smoothly, avoids shaking on the X-axis, and improves your printing accuracy. What's more, a high-quality motor can run efficiently and stably with less noise.

Hope this passage will help you get to know the parts of the 3D printer and lead you into this amazing world! If you have some charge questions, you could visit our other Blogs: How much does a 3D printer cost? If you have some using problems, please go through our Support Center to get common FAQs. See you next page!

Where Can I Get more Information?

3D printers are hot selling around the world. Here are the BIQU Community, and Download Center, where you can search about 3D printers' news or problems solution. If you have any questions, welcome to submit a request to our official website, we will soon settle your problem.

Community & Free 3D Model Files https://biqu3d.com/pages/community

Download the Firmware File https://biqu3d.com/pages/download

Submit a Request https://biqu3d.com/pages/submit-a-ticket

Now there are some general tips for you!

1) You could ask for some advice from a person whom you know, with a fund of professional 3D printer knowledge.

2) If you want to purchase BIQU products, welcome to view BIQU Store!

3) There are some labs, workshops, and maker spaces, where 3D printers are available for trial.

4) You should choose the fittest 3D printer on your own eventually. Considering your demands, work environments, and finances.

5) Whichever company or products you would like to select, please remember to know their sales service and technology support, and even the quality of the accessories and filaments, for they may be an expensive payment.

What's more

If you would like to learn more about the technique and trend of 3D printing and get first-hand information about our new arrivals or discount, you could subscribe to our newsletter!